How are CPG Leaders Reaching Sustainable Packaging Goals?

If we don’t close the gap between rhetoric and action now, our net zero emissions by 2050 goal may slip out of our reach for good. Here’s how 6 consumer packaged goods companies are taking action with sustainable packaging to achieve their corporate sustainability goals.

In May, The International Energy Agency (IEA) reported that current global greenhouse gas emissions and fossil fuel consumption are nowhere near on pace to limit the rise in global temperatures to 1.5 degrees C (the Paris Agreement’s benchmark to avoid the most damaging effects of climate change) and reach our net-zero emissions goal. However, if all stakeholders – governments, businesses, investors, and citizens – close the gap between sustainable rhetoric and action, we can minimize climate change impact.

The CPG industry is navigating cost-efficiency and technical feasibility to decrease the footprint of products and practices across the value chain. Sterling is particularly interested in the evolution of the industry’s approach to packaging, which is essential to protect, contain, and communicate the products we use and consume every day, but contributes to an unignorable percentage of brands’ total scope 3 greenhouse gas emissions today:

In light of this data, Sterling investigated annual reports across the CPG industry to identify 4 critical trends in how leaders are addressing sustainable packaging:

1. Reduce Virgin Plastic

CPG leaders will reduce virgin plastic use by 30% to 50% by 2025. They’re adopting recycled content and alternative packaging materials to decrease their reliance on fossil-based derivatives that produce harmful emissions.

Unilever

Dove’s® “every body is beautiful” mantra extends to their new sustainable packaging initiative to replace virgin plastic with 100% recycled plastic bottles wherever technically feasible, so each bottle can be “beautifully unique.”

Magnum® ice cream collaborated with SABIC to introduce 7 million ice cream tubs made from food-grade recycled plastic that traditional recycling methods could not previously achieve. Magnum is encouraging all pleasure seekers to indulge in “true pleasure, responsibly.”

Nestle®

Smarties® is now the first global confectionery brand to switch to 100% recyclable paper packaging. By adapting existing manufacturing lines to allow for the careful handling required for paper instead of plastic, Smarties is removing 250 million plastic packs sold every year.

PepsiCo

Naked’s® entire juice and smoothie range is the first juice/smoothie brand in grocery retail to achieve 100% rPET compliance. rPET is recycled polyethylene terephthalate – a finite resource that we can grow if we do our part in recycling and increase the available supply.

Naked® has since been divested from the PepsiCo portfolio.

LifeWtr™ also made the switch to 100% rPET in 2020.

Aquafina® water will switch to aluminum can packaging in U.S. food service outlets, and Bubly™ sparkling water will no longer be served in plastic bottles.

2. Optimize Packaging Material

Along with decreasing virgin plastic use, CPG leaders are optimizing the overall amount of packaging material used per consumer by innovating product and packaging forms:

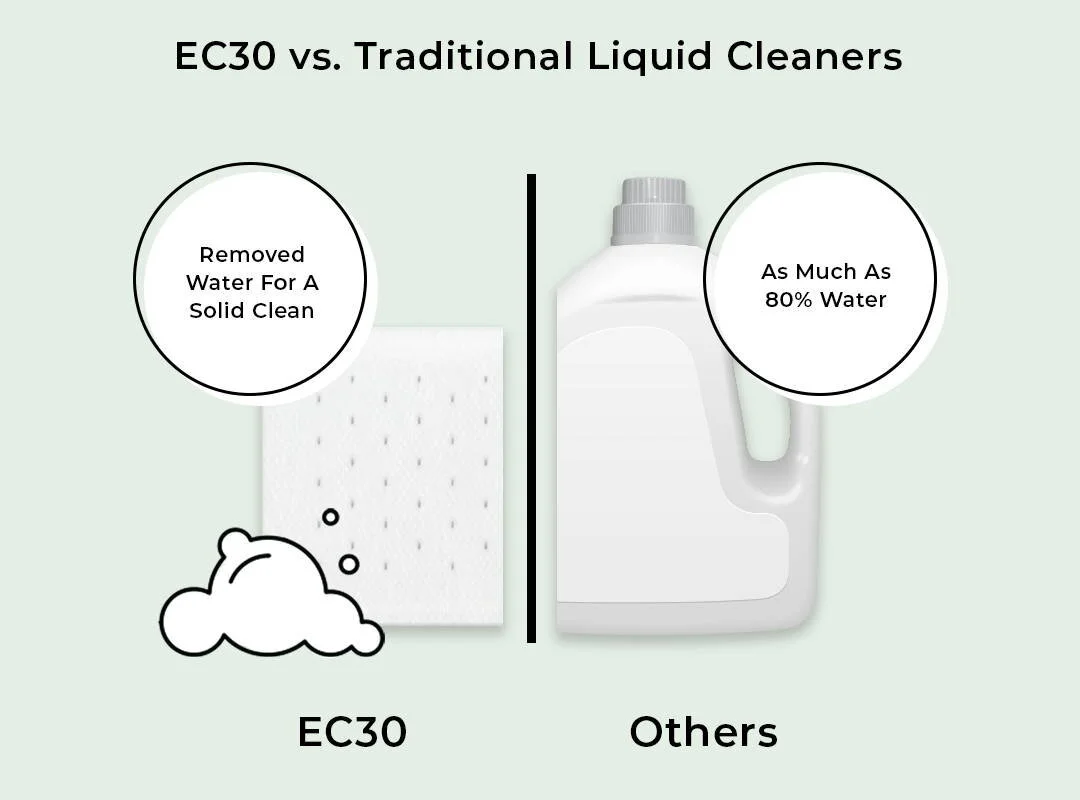

P&G reduced packaging material per consumer use by 12% in 2020 and is continuing this progress with EC30, P&G’s innovative new brand that transforms shampoo, body wash, laundry, and other cleaning agents by eliminating 80% of water weight and 75% associated emissions. If broadly adopted, it could help reduce 12 million pounds of CO2 from the 100,000 trucks that ship 800 million gallons of water in millions of these products.

Tide Eco-Box is an e-commerce solution that reduces the weight and amount of plastic used per package with a re-engineered formula. It offers more cleaning per drop than the original Tide liquid detergent. The cleaning agent is packaged in a shipping-safe box made with 60% less plastic, eliminating the need for secondary re-boxing or bubble wrap.

Johnson & Johnson replaced all plastic pumps on baby products with less than 500 ml volume with a flip-top cap, resulting in approximately 24 million fewer pumps going to landfills.

3. Design for Circularity

CPG leaders are striving to achieve 100% recyclable, reusable, compostable, or biodegradable packaging by 2025, including:

Procter & Gamble

P&G Beauty is replacing plastic bottles for leading brands, including Head & Shoulders®, Pantene, Herbal Essences, and Aussie®. Instead, P&G will adopt reusable aluminum bottles with recyclable refill pouches in Europe to reduce the production of plastic bottles by 300 million annually.

ABInBev:

Michelob® ULTRA partnered with refillable glass bottle marketplace start-up Conscious Container® to launch the “Refill My Beer” program. Consumers who purchased participating products could return empty bottles to Conscious Container bins to be sanitized, inspected, refilled, and recirculated. Recirculated bottles are approximately 5 times less carbon intensive when compared to one-way glass bottles.

4. Improve and Invest

CPG leaders are investing in the recyclables market & associated infrastructure to ensure that products and packaging that are designed to be recyclable are actually recycled.

Johnson & Johnson is educating and encouraging consumers to recycle with their CARE TO RECYCLE initiative.

Unilever invested $15 million in Closed Loop Partners Fund to recycle an estimated 60,000 metric tons of U.S. plastic packaging waste annually by 2025. The investment is part of Unilever’s initiative to collect and process more plastic packaging than it sells by 2025, which helps to secure additional recycled plastic to be used for Unilever brands and also increases access to recycled plastic feedstock processed by the companies the Fund invests in. Furthermore, Unilever is advocating for producer responsibility legislation that would significantly increase the broader investment needed from the industry to transform the recycling system.

At Sterling, “a dedication to sustainable impact” is one of our core values. This means that whether you are a large, established corporation or a scrappy start-up, we collaborate and work towards our mission of always positively impacting your business and the planet we all share.

Learn more by viewing our work.